After a year of bridge, trestle, tunnel, and terrain work, I find myself shifting gears to other projects. Specifically, I have resumed fleshing out the industry served by the railroad. My recent work on the banks of the Willamette River between Eugene and Springfield inspired me to launch into a major industry along the Willamette at Springfield--Borden Chemical. Yes, this is the same Borden known to generations of children and adults as makers of white glue. Borden has been involved in many types of glues and adhesives, including plywood glue. That brings us to the Borden plant in Springfield.

Borden established their Springfield facility in 1960. Though spun off to Momentive today, in the fashion of railroaders everywhere, the historic name sticks. I took a number of photos of the facility in 2013--all from public sidewalks. Still, my photos served as a useful modeling guide.

Momentive chemical plant in Springfield. The Cascade Line mainline is on the right, with the Willamette River bridge showing in the distance. Note the cooling tower with two fan housings near the photo center. Also note the tan steel structure next to the cooling towers. Many of the plant structures follow this scheme.

Chemical plant detail--lots of refining towers, pipes, and even a rail tank car.

Paging through the Walthers catalog for suitable industrial structures, I came upon the corn ethanol plant series issued by Walthers in their Cornerstone ™series. Both plants process plant materials to extract useful chemicals. Though the scale of some of the tanks is off and the implied chemistry modeled is certainly lacking in detail, these kits provided a good base for representing the Momentive facility, at least as it can be seen today. Absent more specific knowledge of both the plant and its historic appearance, I chose to use today's appearance as my guide.

Walthers kits used for this project included:

933-2976, Processing Center

933-2977, Fermentation Tanks

933-2978, Energy Center

933-2979, Cooling Tower Facility

933-4037, Four Modern Loading Racks

Although the Walthers ethanol series was produced only once and is now absent from the catalog, one can find many of these kits on the secondary market yet. I missed obtaining a detail kit for some of the tanks, but will find other ways to add those details later. For now, what I have is sufficient to convey a sense of a large wood chemical plant. To these Walthers kits, I added two of the Vollmer oil refinery kits (770-5525). These added the refining towers and more modest-sized tanks to my facility.

The cooling towers were a relatively late addition to my facility. Looking at photos, such as the one at the top of this article, I realized I should try to add this function. Fortunately, I was able to acquire one of the Walthers cooling tower kits which matches fairly well to the prototype facility. I needed to cut the kit down from four fan housings to two, per the prototype. I did this by cutting both ends off the long walls and cutting an appropriate length roof with fan housings to match. This was necessary because of a center bracing structure for the bottom inlets on the kit walls. This needed to be in the center of my structure. Similarly, I needed to slice the ends off the kit base to retain the center section.

Prototype cooling tower with two fan housings. Although this structure has aluminum-colored walls, I chose to retain the "company look" with tan walls for my model.

Cutting the cooling tower base to fit the shortened (two fan) structure.

Model cooling tower. This part of the model facility is furthest from the river and closest to the rest of the Springfield scene, somewhat like the prototype placement.

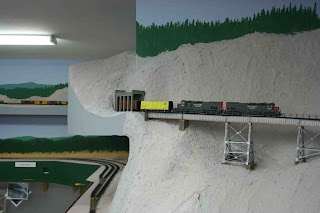

Borden Chemical in place at Springfield on my HO-scale SP Cascade Line.

I still need to add more piping connecting the many pieces of this facility. Still, the vast bulk of the Borden Chemical (Momentive) facility has been built and occupies an important space and function on my railroad.